Overview

Grooved Flange (also known as Grooved End Flange) is a revolutionary pipeline connection component designed for mechanical locking, featuring a grooved end structure that pairs with grooved pipes, gaskets, and locking rings. It eliminates the need for on-site welding or complex threading, offering rapid installation, reliable sealing, and exceptional adaptability. Compliant with global standards, our grooved flanges are engineered with premium materials and precision machining to meet the demands of diverse industrial, commercial, and infrastructure applications—from fire protection systems to industrial pipelines.

Sealing Gasket Options

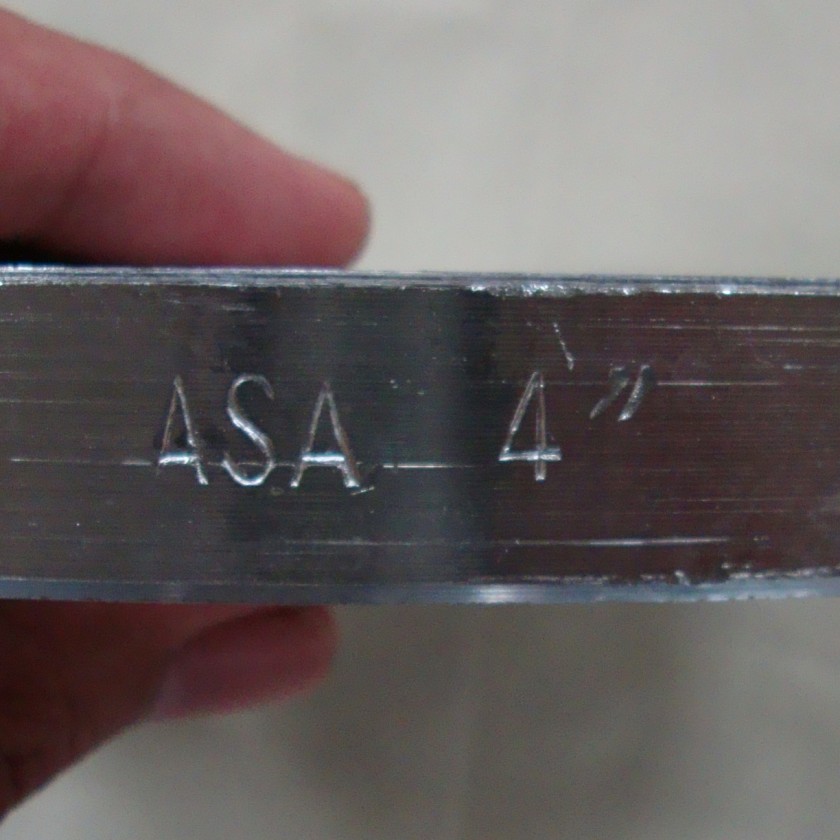

Manufacturing Standards & Certifications

International Standards:

ANSI/AWWA C110/A21.10 (American Water Works Association)

ASME B16.5 (American Society of Mechanical Engineers)

EN 1092-1 (European Standard)

DIN 2501 (German Standard)

GB/T 12465 (Chinese National Standard for grooved pipe fittings)

Quality Certifications: ISO 9001, UL, FM (for fire protection applications), CE.

Quality Control: Each flange undergoes dimensional inspection (CNC measurement), groove precision testing, pressure testing (hydrostatic/air pressure), and surface quality checks to ensure compliance with standard requirements.