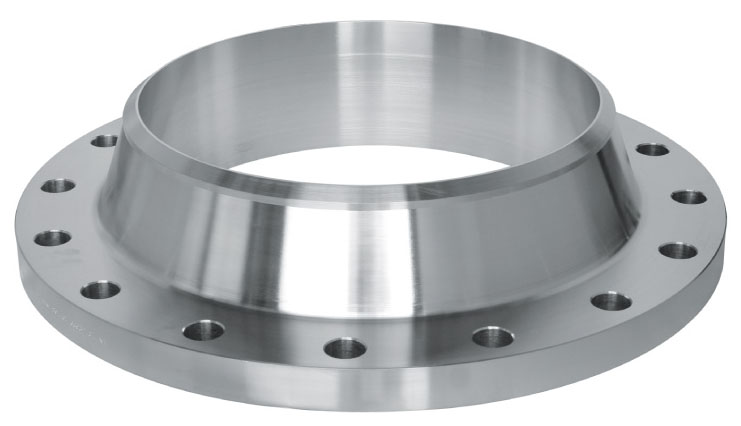

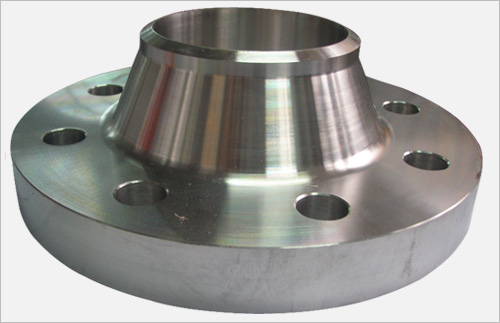

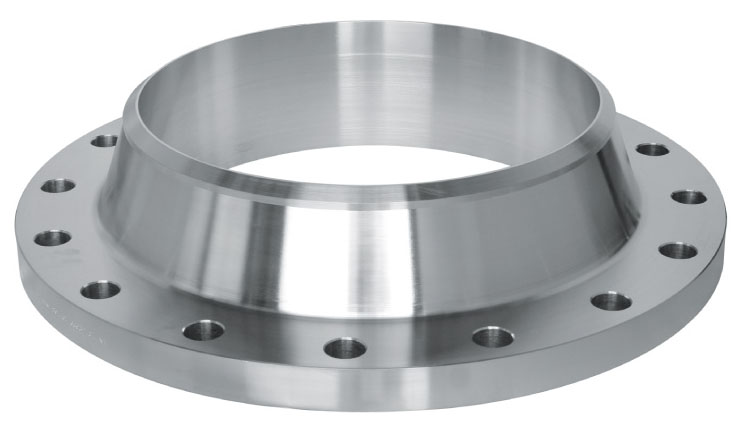

Welding neck flange

Welding neck flange 1. Exceptional structural integrity: Features a integrated neck design that distributes stress evenly, reducing concentration points and enhancing resistance to high pressure, high temperature, and mechanical vibration. 2. Superior sealing performance: Precision-machined sealing surface (RF, FF, RTJ, etc.) ensures tight connection, minimizing leakage risks even in harsh media (corrosive, toxic, high-viscosity) environments. 3. High durability & reliability: Manufactured from high-quality carbon steel, stainless steel (SUS304/SUS316), or alloy steel, with strict heat treatment and quality control, ensuring long service life and stable performance under extreme working conditions. 4. Easy installation & alignment: The neck structure provides clear alignment reference for pipes, simplifying welding and assembly processes, improving construction efficiency, and reducing installation errors. 5. Wide pressure & temperature range: Complies with international standards (ASME B16.5, EN 1092-1, JIS B2220, GB/T 9115) with pressure ratings from PN6 to PN420/Class150 to Class2500, suitable for -200℃ to 800℃ working environments. 6. Versatile application: Ideal for industrial pipelines in oil & gas, chemical, petrochemical, power generation, water treatment, and marine industries, adapting to both standard and custom requirements. 7. Cost-effective in long term: Resistant to wear, corrosion, and fatigue, reducing maintenance frequency and replacement costs, providing long-term economic benefits for industrial systems. 8. Compatibility with international standards: Standardized dimensions and specifications ensure interchangeability with global pipeline components, facilitating cross-border trade and project collaboration.

1. Core Structure

Tapered Neck: Welded to the pipeline via butt welding. Its tapered design enables a smooth transition with the inner wall of the pipeline, significantly reducing stress concentration.

Circular Flange Disc: Equipped with evenly distributed bolt holes for fastening to another flange using bolts. The sealing surface of the disc is designed in various styles based on working conditions, including Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ), etc. Sealing gaskets are used to ensure tightness at the connection.

2. Key Specifications & Parameters

| Parameter Category | Details |

|---|---|

| Size Range | Standard sizes: 1/2" - 60" (equivalent to DN15 - DN1500); Customized models can reach up to 160" (DN4000), adapting to pipeline connection needs of different diameters. |

| Pressure Ratings | Covers multi-standard pressure specifications:- ASME (American Standard): Class150 - Class2500- GB (Chinese Standard) & EN (European Standard): PN2.5 - PN400- JIS (Japanese Standard): 1K - 63K |

| Material Options | Carbon steel (A105, Q235B, 20#), stainless steel (SUS304, SUS316, 316L), alloy steel (F11, F22, 15CrMoV), and corrosion-resistant materials for harsh environments. |

| Sealing Surface Types | Raised Face (RF) - Most commonly used for general high-pressure scenarios;Flat Face (FF) - Suitable for low-pressure, non-toxic mediums;Ring Type Joint (RTJ) - Ideal for ultra-high pressure/temperature oil & gas applications;Male-Female (MF) - Typical for JIS standard flanges, enhancing sealing stability. |

| Execution Standards | International: ASME B16.5, ASME B16.47, EN 1092-1, JIS B2220Domestic: GB/T 9115, HG/T 20592, JB/T 81 |

3. Core Product Advantages

Exceptional Structural Integrity: The integrated neck design distributes stress evenly, resisting high pressure (up to Class2500/PN400), extreme temperatures (-200℃ to 800℃), and mechanical vibration, ensuring long-term stability.

Superior Sealing Performance: Precision-machined sealing surfaces (Ra≤3.2μm) and compatible gaskets minimize leakage risks, even for corrosive, toxic, or high-viscosity media.

Easy Installation & Alignment: The tapered neck provides a clear alignment reference for pipelines, simplifying welding and assembly, reducing installation errors, and improving construction efficiency.

High Durability: Manufactured with high-quality materials and strict heat treatment (quenching, tempering), featuring corrosion resistance, wear resistance, and fatigue resistance, extending service life.

Global Compatibility: Complies with international standards, ensuring interchangeability with global pipeline components, facilitating cross-border trade and project collaboration.

4. Manufacturing Process

5. Typical Applications

Oil & Gas (upstream exploration, midstream transportation, downstream refining)

Chemical & Petrochemical (high-temperature/high-pressure reaction vessels, corrosive medium pipelines)

Power Generation (thermal power, nuclear power boiler pipelines)