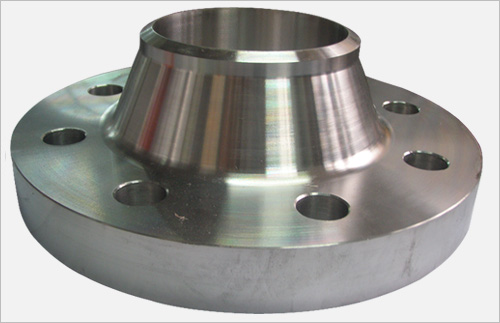

Forged Weld Neck Flange

Direct factory supply eliminates middlemen, offering competitive wholesale prices without compromising quality. Large stock availability for standard models ensures fast delivery (7-15 working days for stock items; 20-30 days for custom orders). Professional technical support and after-sales service guarantee smooth cooperation

Versatile Customization & Wide ApplicationSupports custom sizes (DN15-DN2000/1/2"-80"), materials, and pressure classes to meet specific project requirements. Suitable for pipeline systems in oil & gas, petrochemical, water treatment, marine, HVAC, and boiler industries—one-stop solution for industrial piping needs.

Cost-Effective & Efficient Supply Chain

Eco-Friendly & Sustainable ProductionAdopt energy-saving manufacturing processes and recyclable materials, complying with environmental standards (RoHS, REACH). Low carbon footprint and pollution-free production meet global green industry requirements, helping clients achieve sustainable development goals.

Weld neck flanges, also referred to as WN flanges, are premium piping components designed for high-pressure, high-temperature, and critical industrial applications. Characterized by their integral neck structure that seamlessly transitions to the pipeline, these flanges ensure exceptional structural integrity and stress distribution. Unlike ordinary flanges, the weld neck design minimizes turbulence and erosion at the connection, making them ideal for handling toxic, flammable, corrosive, or high-purity media. Our weld neck flanges are manufactured in strict compliance with international standards, with precise dimensional control and reliable performance, serving as a core connection solution for industrial piping systems worldwide.

Key Specifications

Category

Details

Product Types

Carbon Steel Weld Neck Flange, Stainless Steel Weld Neck Flange, Alloy Steel Weld Neck Flange, Duplex Steel Weld Neck Flange

Manufacturing Process

Forging (open die forging/closed die forging), CNC precision machining, Heat treatment (quenching & tempering, normalizing), Sandblasting, Anti-corrosion coating (hot-dip galvanizing, epoxy painting)

Quality Certification

ISO 9001:2015, CE, API 6A, API 605, RoHS, REACH

Temperature Range

-50℃ to 650℃ (varies by material)

Core Product Advantages

1. Superior Structural Strength & Pressure Resistance

The integral neck design creates a continuous connection between the flange and the pipeline, effectively transferring pipeline stress to the flange body and reducing concentrated stress at the weld. The forged manufacturing process ensures a dense internal structure without porosity, cracks, or other defects, giving the flange excellent pressure-bearing capacity. It is specially designed for high-pressure and high-temperature working conditions, capable of withstanding extreme impact and vibration, and is widely used in Class 600-2500 or PN100-PN160 high-pressure pipeline systems.

2. Excellent Sealing Performance & Media Compatibility

The smooth transition between the neck and the pipeline minimizes fluid turbulence and erosion at the connection, protecting the sealing surface. The sealing face is processed by high-precision CNC machines with a surface finish of Ra 1.6-3.2, ensuring uniform compression of the gasket. For high-pressure and critical applications, the RTJ (Ring Type Joint) sealing structure can be selected to achieve zero leakage. It is suitable for various media such as oil, gas, chemicals, steam, and high-purity fluids, effectively preventing leakage of toxic, flammable, and corrosive media.

3. Strong Corrosion Resistance & Long Service Life

A variety of high-quality materials are available to meet different corrosion resistance requirements. Stainless steel and duplex steel materials have excellent resistance to acid, alkali, salt, and marine environment corrosion; carbon steel and alloy steel can be further enhanced with anti-corrosion treatments such as hot-dip galvanizing and epoxy coating. The product has stable performance in harsh environments, and its service life is 2-3 times longer than that of ordinary slip-on flanges, reducing the frequency of replacement and maintenance.

4. High Precision & Wide Compatibility

Strictly in line with international standards such as ANSI, EN, and DIN, the dimensional tolerance is controlled within ±0.02mm, ensuring perfect matching with pipelines, valves, pumps, and other equipment of the same standard. It is widely applicable to cross-border projects in global petroleum, chemical, power, and marine industries, eliminating compatibility issues in project assembly.

5. Safe Installation & Low Maintenance Cost

The installation adopts fillet weld + butt weld double welding, which ensures a firm and reliable connection and avoids the risk of pipeline detachment. The smooth inner wall of the flange reduces medium deposition and scaling, lowering daily cleaning and maintenance frequency. The reliable performance and long service life significantly reduce long-term operation and maintenance costs for customers.

6. Flexible Customization & Efficient Supply Chain

We support customized production according to customer drawings or samples, including special sizes (DN15-DN3000), materials, pressure classes, and surface treatments. Standard models are in large stock, ensuring fast delivery within 7-15 working days; custom orders can be completed within 20-30 working days, meeting the urgent needs of project construction. As a direct factory, we eliminate middlemen to provide competitive wholesale prices while ensuring product quality.

Application Scenarios

Due to their superior performance, our weld neck flanges are widely used in various critical industrial fields:

Oil & Gas Industry: Exploration, extraction, transportation, and refining pipeline systems; offshore oil platforms

Chemical & Petrochemical Industry: Reactor connections, chemical medium transmission pipelines, petrochemical product processing systems

Power Generation Industry: Thermal power plants, nuclear power plants, renewable energy systems (solar, wind) steam pipelines

Marine & Shipbuilding Industry: Ship piping systems, offshore platform equipment, marine engineering pipelines

Boiler & HVAC Industry: High-temperature steam boiler connections, industrial heating and ventilation systems

Water Treatment & Desalination: Seawater desalination plants, industrial wastewater treatment systems

Quality Control & After-Sales Service

We implement strict quality control throughout the production process, including raw material inspection (chemical composition analysis, mechanical property testing), forging process monitoring, heat treatment quality control, and final dimensional inspection (using 3D measuring instruments). All products undergo pressure testing and non-destructive testing (NDT) such as ultrasonic testing and radiographic testing before leaving the factory. We provide professional technical support, including product selection guidance, installation advice, and after-sales maintenance services, to ensure smooth cooperation and worry-free use for customers.